QUALITY

PLANNING

Quality begins up front with a detailed plan. Before a job is released to the shop, the drawings are reviewed by a team of management, engineers, and inspectors. Each project thoroughly reviewed and agreed upon to make sure everyone has a clear understanding of task at hand.

QUALITY LAB

Every job and every customer have their own requirements. If that requirement demands a higher level of documentation, we’re prepared to deliver with ISO 9001:2015 certification standards. Like our engineers, programmers and machinists, our inspectors use the latest technology software and equipment to get ensure that the fixture is exact to specifications. All of our inspection equipment is maintained and subjected to regular, periodic calibration. For quality control, we utilize two Browne and Sharpe CMM’s as a means of in-process production part control and final inspection, performing repeatability and reliability checks on assembled fixtures.

FINAL INSPECTION

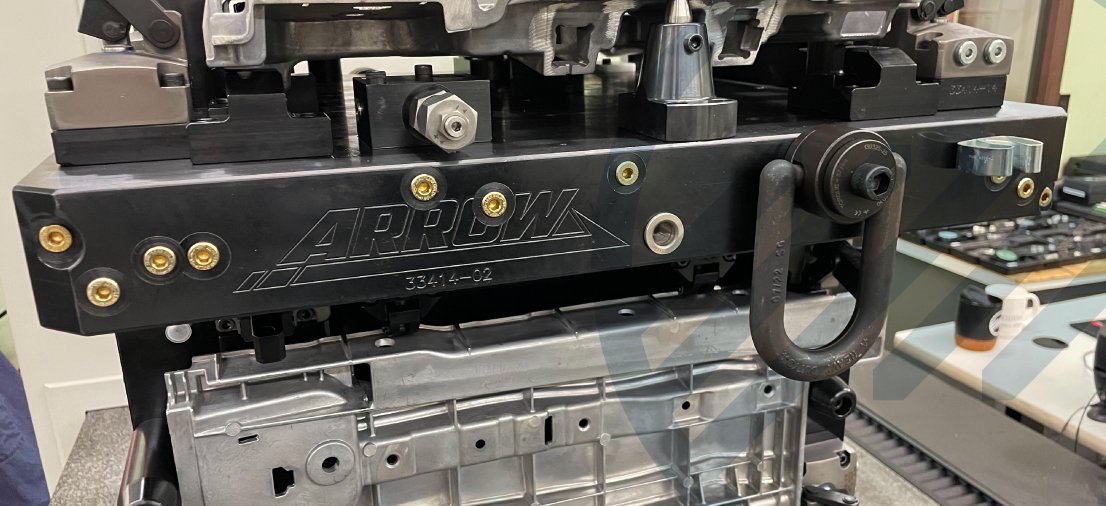

Final inspection of production parts is essential to guaranteeing a quality final product. We’ve developed a detailed check-list to make sure that nothing is overlooked during the design and manufacturing of our fixtures and contract parts. No matter what, Arrow Engineering only ships products that pass our comprehensive inspection standards.

DURABILITY

Delivering a quality and efficient product is at the top of our list at Arrow. We have customers with products and machines that are still in use and over 20 years old. At Arrow Engineering, we also keep documentation and drawings of all of our products for any of our customers retrieval needs. We ensure the reliability of our product through and through.

FUNCTIONAL TESTING

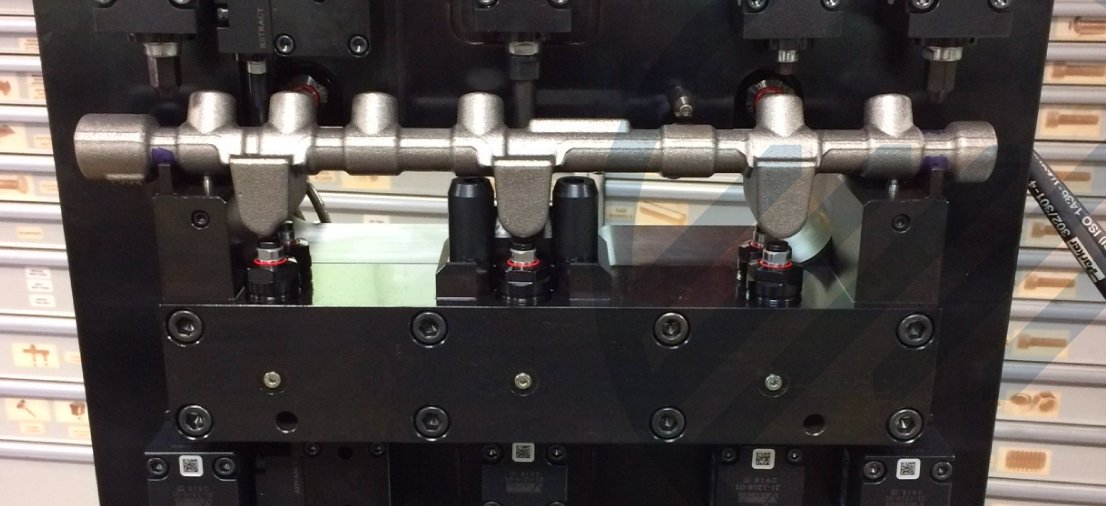

Every fixture is functionally tested by our experienced team to make sure that:

Parts are easy to load and unload

Parts cannot be loaded incorrectly.

Parts are held rigidly, but not deformed by the clamps.

The seals hold under pressure. Every fixture is pressure tested overnight.

There are no sharp edges or other hazards to the operator.